Nano-Scale Liquid Glass Coatings

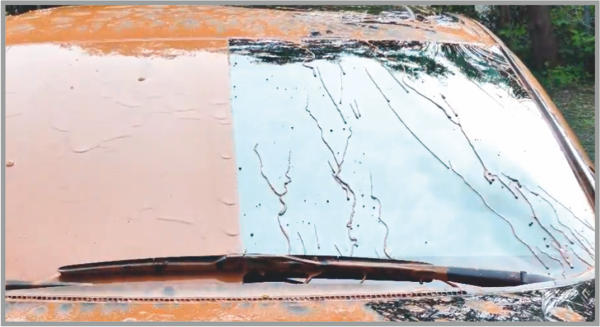

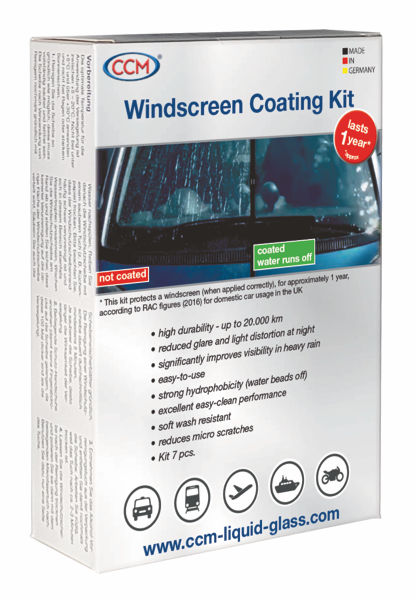

Coating for Windscreens

Tests

| Test according to | Description |

|---|---|

| ASTM E 2546 ISO 14577 | Scratch Test (increase in resistance of a windscreen by 25,6%) |

| Accelerated UV Light Aging test ASTM D 523 ASTM D 2244 | Specular Gloss Calculation of Color Tolerances and Color Differences |

| Laboratory certification | Impact Test |

Effect on E-Vehicles

The CCM Windscreen Coating Technology on E-Vehicles

When driving in winter conditions most E vehicle drivers suffer from Range Anxiety. Do I shut down my car heater? Do I run on side lights? Even using the car radio becomes an issue. It is all going to drain the batteries but it gets worse.

It is winter and you have to drive from London to Manchester, Berlin to Bremen or New York to Washington. The windscreen wipers will be drawing 400 watts for the next 5 hours and this means you have been tipped beyond the battery range because of needing to constantly use your windscreen wipers.

The solution is simple.

Enjoy better vision, and reduce the drain on batteries by using the CCM TUV tested windscreen coating.

Case Study: Coating of a Power Boat

FAQ

1How long does it last?

There is no simple answer to the "How long does it last?“ question. On some cars, which are driven infrequently, the coating can last for several years, but if one applies the coating to a taxi which drives 300 miles per day around Long Island, where there is a frequent rain (and sand from local beaches) the coating will last for a shorter period. Formal lab testing informs us that that the coating lasts for the equivalent of 20,000 km but it is proposed that under standard driving conditions one application will last for approximately 6 months (on the taxi windscreen example it may last for only 3 months).

The main impact on the performance of the coating is associated with

A. Quality of application.

B. The amount of abrasion which the screen is subjected to.

Another example:

if a car drives 20,000km around the US during a month-long road trip, in the early summer, it is possible that the windscreen wipers will have been used for only a matter of minutes. After 20,000km the coating will have experienced very little degradation (unless driving closely behind vehicles when transiting a desert) and it will retain strong performance.

If the same road trip is made in the autumn, when there is significantly more light rain, it is possible that the windscreen wipers will have been used on many occasions. This windscreen wiper action will start to abrade the surface. Light, misty rain does not immediately run off the coated windscreen at low speeds and so the windscreen wiper will be used

If the same road trip is made in the winter and let us assume that the rain is torrential, it is highly probable that the windscreen wipers will only need to have been used on rare occasions as heavy / torrential rain runs off the windscreen very rapidly.

Having noted the above one application of the windscreen coating should last for approximately 6 months +/- under normal usage conditions.

The main impact on the performance of the coating is associated with

A. Quality of application.

B. The amount of abrasion which the screen is subjected to.

Another example:

if a car drives 20,000km around the US during a month-long road trip, in the early summer, it is possible that the windscreen wipers will have been used for only a matter of minutes. After 20,000km the coating will have experienced very little degradation (unless driving closely behind vehicles when transiting a desert) and it will retain strong performance.

If the same road trip is made in the autumn, when there is significantly more light rain, it is possible that the windscreen wipers will have been used on many occasions. This windscreen wiper action will start to abrade the surface. Light, misty rain does not immediately run off the coated windscreen at low speeds and so the windscreen wiper will be used

If the same road trip is made in the winter and let us assume that the rain is torrential, it is highly probable that the windscreen wipers will only need to have been used on rare occasions as heavy / torrential rain runs off the windscreen very rapidly.

Having noted the above one application of the windscreen coating should last for approximately 6 months +/- under normal usage conditions.

2How does it help to repel water?

The windscreen coating is made from nano scale glass. This new glass layer is very hydrophobic. Water will "bead up" and slide off the slippery glass surface. The coating is only 100nm thick (500 times thinner than a human hair.) It is both super hard, yet flexible at the same time.... this is why it is so durable... the wonders of nano technology!

3How often do you apply the coating?

As noted above, it all depends on weather and environmental conditions but as a general rule application every 6 months is recommended, having noted this, we recommend that after the very first application a second application may be suitable at the 4-month mark. Then every six months afterwards.

4How do you prepare the area you will apply to?

Always wash the areas on the windshield that you will apply liquid glass coating to with a suitable cleaning agent. We suggest Biosativa as the best cleaner. Ensure that you thoroughly rinse the screen as washing liquid and similar cleaning agents leave a tenside residue on the surface. This must be rinsed off. It normally takes at least 5 minutes to thoroughly clean a windscreen. After rinsing and drying the screen, deep clean the surface using the cleaning wipe (usually noted as No "1").

Allow the screen to dry for 2 minutes after wiping with the alcohol cleaning cloth then buff the screen and remove the light film which will appear after wiping the area with the alcohol wipe (Use a clean cloth or tissue).

Application of the coating:

Wipe the windscreen with the coating cloth (No "2"). Work quickly and methodically ensuring full coverage of the screen. The cloth will dry within approximately 90 seconds. Vertical and Horizontal wiping actions are recommended.

Use suitable disposable gloves when cleaning and coating. A fingerprint can be 100 times thicker than the coating!

Application of the coating:

Wipe the windscreen with the coating cloth (No "2"). Work quickly and methodically ensuring full coverage of the screen. The cloth will dry within approximately 90 seconds. Vertical and Horizontal wiping actions are recommended.

Use suitable disposable gloves when cleaning and coating. A fingerprint can be 100 times thicker than the coating!

5How long does liquid glass guard take to dry?

Approximately 5 minutes in warmer weather and 20 minutes in colder weather (see back of wipes).

After Drying: You will see that there is a haze on the surface. This is completely normal. Please use a clean and dry microfibre cloth to buff the surface. The buffing action may take up to 5 minutes.

After Drying: You will see that there is a haze on the surface. This is completely normal. Please use a clean and dry microfibre cloth to buff the surface. The buffing action may take up to 5 minutes.

6Can you apply liquid glass guard outside?

Yes, you can apply outside. It’s best applied in a shaded area. Do not apply when very humid or when rain is expected within minutes of application. Do not apply in direct "hot" sunlight.

If applying in a garage, please remember that the wipes contain alcohol and are combustible.

Do not apply on to a hot windscreen. 5-20°C is the suggested surface temperature.

7Can it be removed?

Yes. By using a combination of wire wool (0000) and cerium oxide.

8Can the nano particles in the liquid damage the body of my vehicle?

We do not work with discrete nano particles, the SiO² is amorphous molecular scale SiO². Our Liquid Glass coatings are designed as wet-chemical coatings. The dried coatings are approximately 100nm (nanometres) thin and therefore fall under the official definition of “nanotechnology” (“structures” <=100 nm). If the coating does come into contact with the body work, we suggest that area is buffed as soon as possible.

The windscreen coating is designed specifically for application to glass.

Maintenance: The coating is very resistant to soiling but micro contamination from vehicle exhausts will sit on the surface. Over time it will be necessary to remove this contamination. Wash the surface with Biosativa or alcohol and the coating will become rejuvenated.

Maintenance: The coating is very resistant to soiling but micro contamination from vehicle exhausts will sit on the surface. Over time it will be necessary to remove this contamination. Wash the surface with Biosativa or alcohol and the coating will become rejuvenated.

9Does the coating withstand freezing conditions?

Yes, the coating does withstand freezing. You will also notice improved visibility when driving in snow.

Instructions for Use

- Preparation

- Preparation Step 1

- Preparation Step 2

- Preparation Step 3

- Preparation Step 4

- Preparation Step 5

- Application Step 1

- Application Step 2

- Application Step 3

- Application Step 4

The optimum temperature to apply the windscreen coating is between +5 to +20°C. Do not apply at lower than 5°C or above 30°C. It is essential that the windscreen is completely clean before the application of the coating. In many instances the end user considers that a windscreen is clean after wiping the surface with a cleaning agent until it looks clean. This is not the case! Thorough preparation is required before applying our coatings. On average it takes a minimum of 5 minutes to clean a windscreen, however it may take 10 minutes to clean a highly contaminated windscreen. A clean screen = enhanced performance.

It is suggested that the windscreen is washed thoroughly with water and a microfiber cloth (not the one which is enclosed in the pack). Please ensure that no residues from cleaning agents are left on the surface as residues prevent the layer of SiO² (pure glass) from bonding. The layer formed is only 100nm thick (500 times thinner than a human hair). This layer is massively durable, but as can be imagined, this ultra-thin layer can only bond efficiently to a completely clean and dry surface. This initial cleaning will remove heavy contamination such as insect residue, traffic film etc. We do not suggest using washing-up liquid, as this places tenside residues on the windscreen. Surfactant-free cleaning agents are recommended. Rinse the screen thoroughly.

Dry the windscreen with a clean cloth or suitable kitchen roll/absorbent paper. Please note that the perimeter of the screen is often heavily soiled, and also drops of water can remain in this area. Wipe the perimeter of the windscreen, ensuring that any soiling agents are not transferred to the rest of the windscreen. Finally, wipe the windscreen wiper blades to remove heavy contamination.

Now put on the enclosed gloves, as a fingerprint can be 100 times thicker than the coating.

Deep clean the screen with the enclosed alcohol wipe (No. 1). All windscreens differ in the amount of contamination held within the micro scratches (all screens have such scratches). Wipe the screen with the supplied wipe or use a suitable alcohol cleaner. The cleaner must be free of any additional polishing agents. Continue to wipe the surface until the screen is completely clean. Ensure correct safety controls are followed when using alcohol. Follow the MSDS guidelines. Test alcohol cleaners such as IPA on an inconspicuous area.

After cleaning with the alcohol-based wipe, allow the screen to dry and then buff the screen with one side of the enclosed microfibre.

Apply the coating to the windscreen (wipe No. 2). Working quickly, ensure full coverage of the screen. Wipe with both vertical and horizontal actions to ensure full coverage. Continue wiping until the wipe becomes dry, (approximately 90 seconds when the temperature is 15-20 °C) It is recommended that the outer edge of the screen is wiped at the last moment to avoid any possible contamination of the central area of the screen. Finally wipe the coating cloth along the wiper blade rubber. The pre-impregnated wipe contains 6ml of coating. This is optimised for coating a car windscreen. (Please use 2 coating wipes for lorries, vans or large vehicles)

Allow the coating to dry for approximately 5 to 30 minutes. (5 minutes in warm weather e.g. 25°C… 30 minutes in cool weather e.g. 10°C).

After application the surface may look slightly “cloudy”. Buff the surface with the clean side of the enclosed micro-fibre to remove any residue which contributes to the cloudy appearance.

The coating takes 10 hours to fully cure, but the windscreen can be exposed to rain one hour after application. Avoid using the windscreen wipers within the first 10 hours, but in some instances they may have to be used. This can slightly reduce the length of time that the coating remains in place. Do not apply the coating in damp or very humid conditions. The coating wipes within the kit will provide protection for a windscreen for approximately 1 year if applied correctly, based on average yearly figures in the UK. Do not apply the coating in hot, direct sunlight. Do not apply our SiO² based coating to windscreens which are coated with other agents such as car waxes, polishes etc. Do not apply the coating to hot windscreens (in hot regions of the world it is best to apply the coating early in the morning or in the evening, when often the windscreen is cooler). Do not apply when the air temperature or glass temperature is greater than 30°C.The enclosed wipe will coat up to 2m² if the temperature of the glass is up to 20°C higher glass temperature will reduce the coverage per wipe.

More Products

Car Coatings

CCM offer a world class portfolio of coatings, for almost all surfaces known to man, including the wide range of surfaces found in the auto, marine, healthcare, industrial, sporting, agricultural, aviation, military and domestic environments. The coatings range from simple „wipe and go“ type coatings, to ultra-durable, military grade coatings which are designed for professional application.